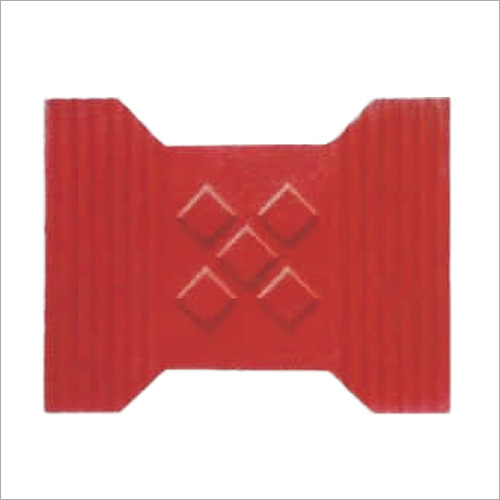

Tourus Paver Moulds

Tourus Paver Moulds Specification

- Molding Material

- Concrete mix, resin

- Mold Base

- Plastic

- Usage

- Industrial

- Shaping Mode

- Paver Moulds

- Material

- Plastic

- Mould Weight

- Approx 500 Grams (g)

Tourus Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Tourus Paver Moulds

Versatile Moulding Choices

Whether you need to work with concrete or resin, Tourus Paver Moulds offer compatibility and flexibility. These plastic moulds are engineered to ensure smooth shaping and easy release, making them suitable for diverse industrial paving requirements. Their versatility supports both small and large-scale production environments.

Industrial Durability and Precision

Constructed from high-quality plastic, Tourus Paver Moulds boast resilience and precision. Their lightweight construction allows for easy handling, while the robust material extends their usable lifespan even in demanding conditions. The mould design helps achieve consistently shaped and detailed pavers for commercial projects.

FAQs of Tourus Paver Moulds:

Q: How are Tourus Paver Moulds used in industrial settings?

A: Tourus Paver Moulds are used in industrial environments by filling them with a concrete mix or resin. Once the material sets within the plastic mould, it forms durable, consistently shaped paver blocks ready for further processing or installation.Q: What materials can be molded using these paver moulds?

A: These moulds are compatible with both concrete mixes and resin, making them adaptable for different industrial paving applications and project requirements.Q: When should I use plastic-based moulds for paver production?

A: Plastic-based moulds are best used when you require repeatable precision, easy handling, and cost-effective durability in producing paver blocks, especially in high-volume or continuous manufacturing processes.Q: Where can Tourus Paver Moulds be sourced?

A: Tourus Paver Moulds can be sourced directly from us as we are an established importer, manufacturer, supplier, and service provider based in India, catering to clients across the nation.Q: What is the process of making paver blocks with these moulds?

A: To create paver blocks, mix your chosen molding material (concrete or resin), pour it into the clean mould, allow it to cure or set as required, then demould for a finished product that is ready for use.Q: What are the primary benefits of using Tourus Paver Moulds?

A: The main benefits include high durability, ease of use, consistent block quality, and suitability for rapid and repeated production cycles, providing significant value in large-scale or customized paving projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

Falcon Paver Moulds

Minimum Order Quantity : 1 Unit

Material : Plastic

Molding Material : Concrete mix, resin

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Shaping Mode : Other

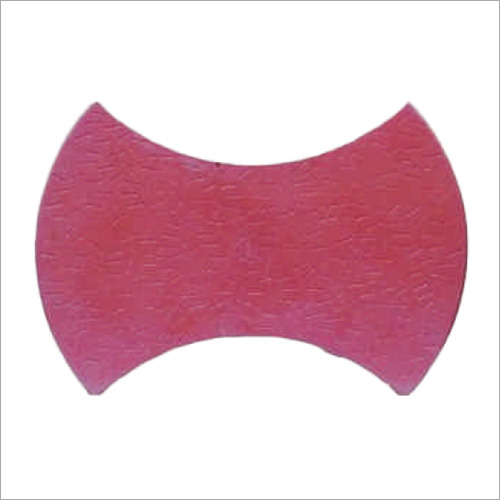

Damaru Paver Moulds

Minimum Order Quantity : 1 Unit

Material : Plastic

Molding Material : Concrete mix, resin

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Shaping Mode : Other, Paver Moulds

Brooks Paver Moulds

Minimum Order Quantity : 1 Unit

Material : Plastic

Molding Material : Concrete mix, resin

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Shaping Mode : Other, Paver Moulds

Zig Zag Paver Moulds

Minimum Order Quantity : 1 Unit

Material : Plastic

Molding Material : Concrete mix, resin

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Shaping Mode : Plastic Extrusion Mould

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry