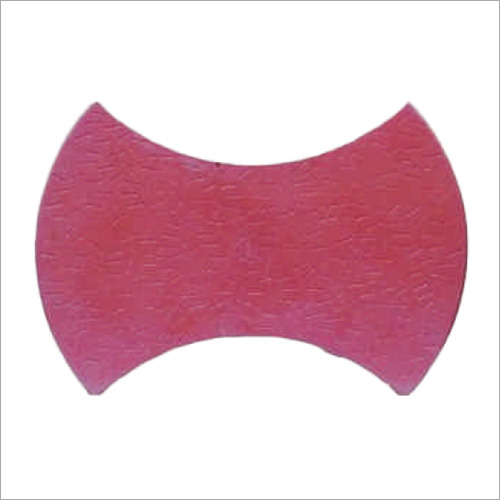

Damaru Paver Moulds

Damaru Paver Moulds Specification

- Mold Base

- Plastic

- Molding Material

- Concrete mix, resin

- Usage

- Industrial

- Shaping Mode

- Paver Moulds

- Material

- Plastic

- Size

- Standard

- Mould Weight

- Approx 500 Grams (g)

Damaru Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Damaru Paver Moulds

Robust and Reliable Mold Construction

Manufactured from high-quality plastic, Damaru Paver Moulds offer exceptional durability and resilience against frequent industrial usage. Their robust design ensures long-lasting performance even under demanding production conditions. This reliability makes them an excellent choice for businesses in need of consistent and repeatable paving results.

Versatile Usage Across Materials

These moulds are engineered to work efficiently with both concrete and resin mixes, providing flexibility in paver production. Their versatility allows manufacturers to cater to diverse client needs, whether using traditional concrete or innovative resin materials for their paving solutions.

FAQs of Damaru Paver Moulds:

Q: How are Damaru Paver Moulds used in the industrial paver manufacturing process?

A: Damaru Paver Moulds are filled with a concrete or resin mix, ensuring it is evenly distributed. After curing, the mould is removed to reveal a standard-sized paver, ready for industrial application. Their user-friendly design simplifies both the filling and demoulding processes.Q: What materials can be used with these paver moulds?

A: These moulds are compatible with both concrete mix and resin, offering flexibility for various paving projects. This allows manufacturers to produce pavers that meet specific strength or aesthetic requirements.Q: When should these moulds be chosen over other types?

A: Damaru Paver Moulds are ideal when you require standard-sized, uniform pavers for industrial paving purposes. Choose these moulds if you need dependable, lightweight tools that facilitate high-volume production efficiently.Q: Where are these paver moulds typically supplied or used?

A: These moulds are widely supplied across India and are predominantly used by importers, manufacturers, service providers, and suppliers involved in industrial paving and construction projects.Q: What is the typical usage process for these paver moulds?

A: Simply pour the prepared concrete or resin mix into the mould, ensure proper compaction, and allow it to cure. Once hardened, carefully remove the mould to produce a durable, standard-sized paver ready for installation.Q: What are the main benefits of using Damaru Paver Moulds?

A: Key benefits include ease of use, consistent paver shapes, compatibility with multiple materials, and robust plastic construction that ensures reliability for repeated industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

Vaves Paver Moulds

Minimum Order Quantity : 1 Unit

Molding Material : Concrete mix, resin

Material : Plastic

Usage : Industrial

Shaping Mode : Injection Mould

Mold Base : Plastic

Badam Cosmic Paver Moulds

Minimum Order Quantity : 1 Unit

Molding Material : Concrete mix, resin

Material : Plastic

Usage : Industrial

Shaping Mode : Injection Mould

Mold Base : Plastic

Brooks Paver Moulds

Minimum Order Quantity : 1 Unit

Molding Material : Concrete mix, resin

Material : Plastic

Usage : Industrial

Shaping Mode : Other, Paver Moulds

Mold Base : Plastic

Coasmic Paver Moulds

Minimum Order Quantity : 1 Unit

Molding Material : Concrete mix, resin

Material : Plastic

Usage : Industrial

Shaping Mode : Injection Mould

Mold Base : Plastic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free