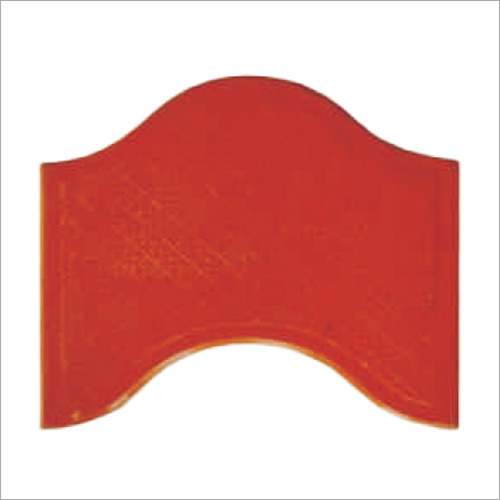

Zig Zag Paver Moulds

Zig Zag Paver Moulds Specification

- Molding Material

- Concrete mix, resin

- Mold Base

- Plastic

- Shaping Mode

- Plastic Extrusion Mould

- Usage

- Industrial

- Material

- Plastic

- Size

- Standard

- Mould Weight

- Approx 500 Grams (g)

Zig Zag Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Zig Zag Paver Moulds

Durability Meets Efficiency

Constructed from superior plastic and built to handle rigorous industrial settings, the Zig Zag Paver Moulds offer outstanding resilience and sustained performance. Their robust design resists deformation, ensuring that each paver block retains precise dimensions, contributing to faster production and reduced material wastage.

Precision Molding Technology

Utilizing a plastic extrusion shaping mode, these moulds guarantee uniform thickness and sharp detailing on every paver. The process is highly efficient and compatible with concrete mix or resin, allowing flexibility and adaptability for different project requirements.

FAQs of Zig Zag Paver Moulds:

Q: How are Zig Zag Paver Moulds used in the manufacturing process?

A: To use Zig Zag Paver Moulds, fill each plastic mould with a concrete mix or resin, ensuring an even spread. After allowing the material to cure and harden, demould to release precise zig zag-shaped blocks. This method provides consistent, high-quality results, ideal for industrial-scale production.Q: What materials can be molded with these paver moulds?

A: The Zig Zag Paver Moulds can be used with both concrete mix and resin, offering flexibility according to your specific project requirements. Their sturdy plastic mold base helps achieve quality results with different molding materials.Q: When is it ideal to use zig zag paver blocks produced with these moulds?

A: Zig zag paver blocks are recommended for surfaces requiring enhanced load-bearing strength, such as industrial floors, driveways, pavements, and walkways. Their interlocking pattern ensures durability and increased resistance to shifting under heavy loads.Q: Where can these paver moulds be sourced in India?

A: These Zig Zag Paver Moulds are available from reputed importers, manufacturers, service providers, and suppliers throughout India. Contacting a trusted supplier ensures product quality, reliable delivery, and efficient customer support.Q: What is the benefit of using plastic mould bases for paver block production?

A: Plastic mould bases are lightweight (approximately 500 grams), durable, and resistant to repeated use and chemical corrosion. They enable easy demoulding, maintain the integrity of every paver, and reduce overall maintenance costs over time.Q: What is the typical process flow for creating paver blocks using these moulds?

A: The process involves preparing your concrete mix or resin, pouring it into the mould, allowing it to set and cure, and then releasing the finished product. The moulds plastic extrusion shaping mode ensures accuracy and efficient production cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

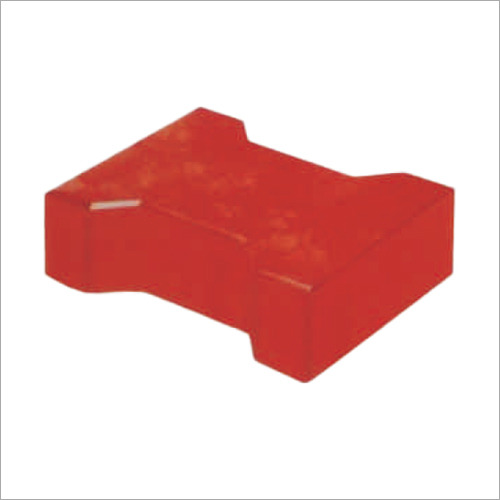

Jumbo Colorado Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Paver Mould

Usage : Industrial

Mold Base : Plastic

Mould Weight : Approx 500 Grams (g)

Material : Plastic

Grooks Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Paver Moulds

Usage : Industrial

Mold Base : Plastic

Mould Weight : Approx 500 Grams (g)

Material : Plastic

Falcon Plain Paver Mould

Minimum Order Quantity : 1 Unit

Shaping Mode : Plastic Extrusion Mould

Usage : Industrial

Mold Base : Plastic

Mould Weight : Approx 500 Grams (g)

Material : Plastic

Vaves Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Injection Mould

Usage : Industrial

Mold Base : Plastic

Mould Weight : Approx 500 Grams (g)

Material : Plastic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry