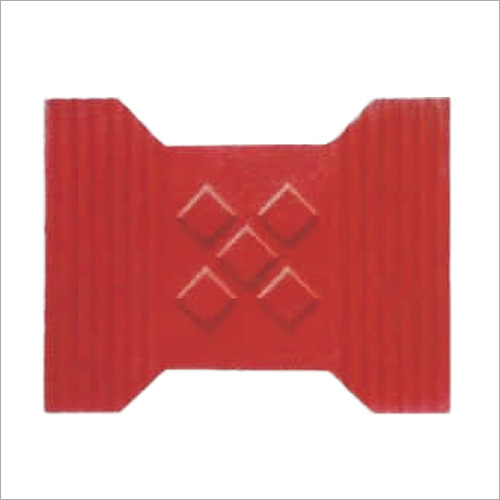

Falcon Paver Moulds

Falcon Paver Moulds Specification

- Molding Material

- Concrete mix, resin

- Mold Base

- Plastic

- Shaping Mode

- Other

- Usage

- Industrial

- Material

- Plastic

- Size

- Standard

- Mould Weight

- Approx 500 Grams (g)

Falcon Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

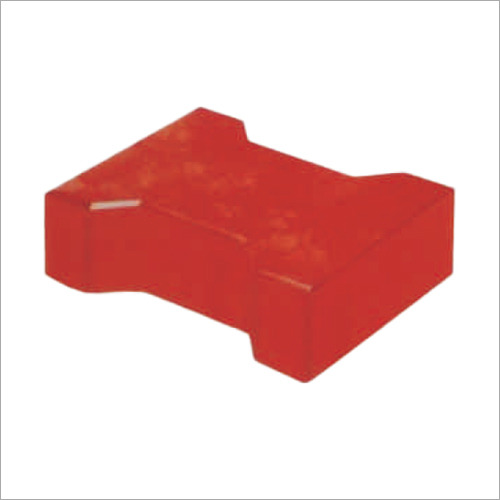

About Falcon Paver Moulds

Premium-Quality Industrial Paver Moulds

Falcon Paver Moulds are designed to maintain consistency and strength during the production of concrete pavers in industrial environments. Crafted from durable plastic, these moulds help deliver precise shapes and smooth finishes every time. Their standard size ensures compatibility with commonly used paving designs, while their lightweight construction (approx. 500 grams per mould) makes them easy to handle and transport.

Engineered for Efficiency and Reusability

Our paver moulds are specifically developed for use with concrete mixes and resins, ensuring flexibility in material selection. The sturdy plastic construction allows for multiple production cycles without compromising the moulds integrity, ultimately reducing replacement costs. Ideal for importers, manufacturers, and service providers, our moulds streamline paver manufacturing and promote operational efficiency.

FAQs of Falcon Paver Moulds:

Q: How are Falcon Paver Moulds used in industrial applications?

A: Falcon Paver Moulds are utilized by filling them with a concrete or resin mix and allowing it to set. Once cured, the mould is opened to release the finished paver block, which is then ready for installation in industrial flooring or pavement projects.Q: What materials are compatible with Falcon Paver Moulds?

A: These moulds are suitable for use with concrete mix and resin, allowing manufacturers to produce durable and high-quality paver blocks according to project requirements.Q: When should these moulds be replaced or maintained?

A: Regular visual inspection is recommended. While the plastic material supports repeated use, if you notice significant warping, cracks, or difficulty in releasing finished pavers, it may be time to replace the mould.Q: Where can Falcon Paver Moulds be purchased or sourced in India?

A: Falcon Paver Moulds are available through Falcons distribution network across India. As an importer, manufacturer, and supplier, Falcon can be contacted directly for bulk or customized orders.Q: What is the process involved in making paving blocks with these moulds?

A: The process involves pouring a prepared concrete or resin mix into the mould, vibrating it to eliminate air pockets, and then letting it cure. After curing, the mould is carefully removed, yielding a uniform paver block ready for use.Q: What benefits do Falcon Paver Moulds offer for manufacturers and service providers?

A: These moulds facilitate the efficient, cost-effective, and repeatable production of high-quality paver blocks, ensuring consistency and minimizing defects during manufacturing.Q: How do these moulds improve the quality of finished paver blocks?

A: The robust plastic base and standardized design contribute to precise shaping, even surfaces, and consistent dimensions, all crucial for interlocking pavers used in industrial and commercial pavements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

Badam Cosmic Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Molding Material : Concrete mix, resin

Material : Plastic

Falcon Plain Paver Mould

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Molding Material : Concrete mix, resin

Material : Plastic

Zig Zag Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Molding Material : Concrete mix, resin

Material : Plastic

Brooks Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Molding Material : Concrete mix, resin

Material : Plastic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry