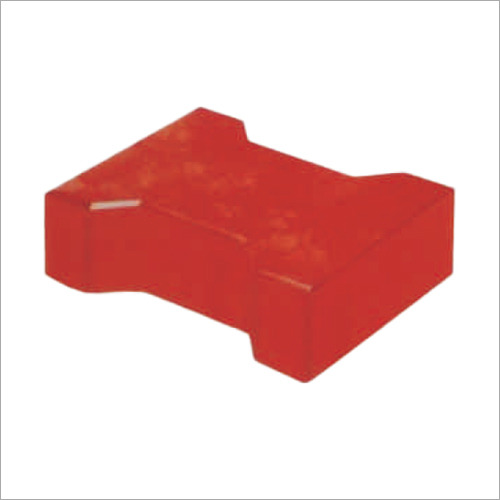

Falcon Plain Paver Mould

Falcon Plain Paver Mould Specification

- Molding Material

- Concrete mix, resin

- Mold Base

- Plastic

- Usage

- Industrial

- Shaping Mode

- Plastic Extrusion Mould

- Material

- Plastic

- Size

- Standard

- Mould Weight

- Approx 500 Grams (g)

Falcon Plain Paver Mould Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Falcon Plain Paver Mould

Precision Engineering for Uniform Pavers

Our Falcon Plain Paver Mould is engineered to deliver perfectly consistent paver blocks every time. Thanks to its robust plastic construction and precise extrusion shaping, users can expect high-quality results, reducing wastage and rework in large-scale paver manufacturing projects.

Versatile Industrial Application

Designed for industrial use, this mould accepts various molding materials, such as concrete mix and resins, offering flexibility for different project requirements. Its standard size and lightweight design provide ease of handling, whether in small-batch or continuous production environments.

FAQs of Falcon Plain Paver Mould:

Q: How should I use the Falcon Plain Paver Mould for the best results?

A: To achieve optimal paver quality, ensure the mould is clean and properly lubricated before filling it with concrete mix or resin. Pour the mixture evenly and settle it by tapping or vibrating to eliminate air bubbles. Allow adequate curing time before demoulding to maintain the integrity and finish of each paver.Q: What materials are compatible with this mould?

A: The Falcon Plain Paver Mould is designed to work seamlessly with concrete mix and various resins. These materials flow smoothly into the mould, taking on a precise shape and texture with every use.Q: When should the mould be removed after casting?

A: It is recommended to demould the paver only after the mixture has sufficiently set and achieved initial strength, generally after 24 to 48 hours of curing, depending on ambient conditions and material used.Q: Where can these moulds be used in industrial settings?

A: These moulds are suitable for use in manufacturing units, construction companies, and by service providers specializing in paving block production. They are distributed across India and can be sourced from importers, manufacturers, and suppliers.Q: What is the process for cleaning and maintaining the moulds?

A: After each casting, wash the mould with mild detergent and water to remove any residue. Ensure the mould is completely dry before storing or reusing. Regular maintenance extends the life of the mould and ensures high-quality paver output.Q: How does the plastic extrusion shaping mode benefit the user?

A: Plastic extrusion shaping provides precise, repeatable results, minimizing defects and ensuring consistent paver thicknessan important factor for industrial paving applications.Q: What are the main benefits of using Falcon Plain Paver Moulds for industrial paver production?

A: These moulds offer excellent durability, reusability, and ease of handling. Their precise dimensions and high-quality plastic construction guarantee consistent output, reducing overall operational costs and improving project timelines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

Brooks Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Paver Moulds

Material : Plastic

Mould Weight : Approx 500 Grams (g)

Mold Base : Plastic

Usage : Industrial

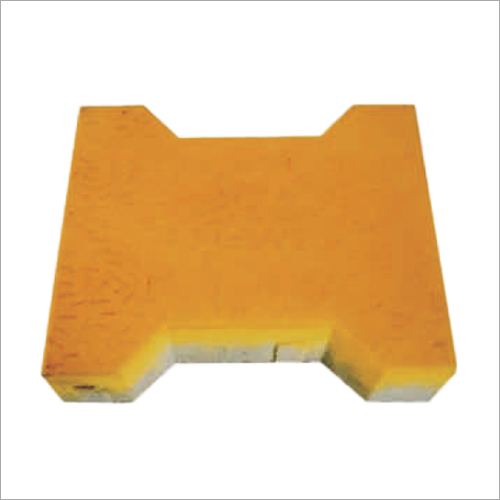

Jumbo Colorado Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Paver Mould

Material : Plastic

Mould Weight : Approx 500 Grams (g)

Mold Base : Plastic

Usage : Industrial

Coasmic Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Injection Mould

Material : Plastic

Mould Weight : Approx 500 Grams (g)

Mold Base : Plastic

Usage : Industrial

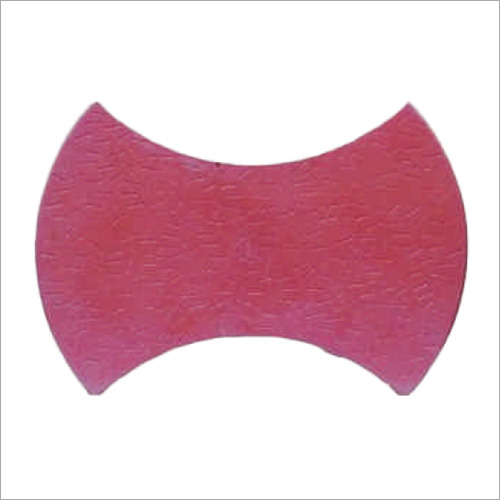

Damaru Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Paver Moulds

Material : Plastic

Mould Weight : Approx 500 Grams (g)

Mold Base : Plastic

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry