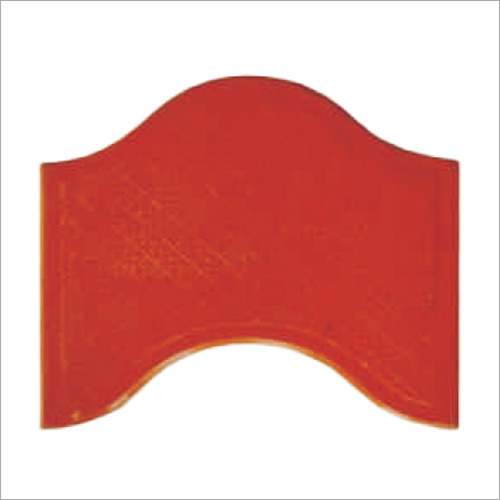

Badam Cosmic Paver Moulds

Badam Cosmic Paver Moulds Specification

- Mold Base

- Plastic

- Molding Material

- Concrete mix, resin

- Usage

- Industrial

- Shaping Mode

- Injection Mould

- Material

- Plastic

- Size

- Standard

- Mould Weight

- Approx 500 Grams (g)

Badam Cosmic Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Badam Cosmic Paver Moulds

Precision Engineering for Superior Paver Blocks

Badam Cosmic Paver Moulds are manufactured using advanced injection moulding techniques, ensuring precise shapes and consistent dimensions. The use of durable plastic as a mould base guarantees longevity and repeated usage, making them a smart investment for industrial-scale paver block production.

Optimized for Industrial Applications

Designed for industrial use, these moulds fit seamlessly into existing manufacturing setups. Their standard size and lightweight profile enable easy integration and handling, streamlining the production process for both small and large enterprises across India.

FAQs of Badam Cosmic Paver Moulds:

Q: How are Badam Cosmic Paver Moulds used in the production process?

A: Badam Cosmic Paver Moulds are used by filling them with a suitable concrete mix or resin. After pouring, the material is allowed to set within the mould, and once cured, the mould is removed to reveal a precisely shaped paver block.Q: What materials are compatible with these moulds?

A: The moulds are specifically designed to work with concrete mixes and resin, providing flexibility to manufacturers based on their production requirements.Q: When is it recommended to use these paver moulds?

A: These moulds are recommended for industrial applications requiring mass production of paver blocks, especially when durability and precision are key considerations.Q: Where can I source Badam Cosmic Paver Moulds in India?

A: Badam Cosmic Paver Moulds are available through authorized importers, manufacturers, service providers, and suppliers across India. They can be purchased directly from reputable industry suppliers.Q: What is the shaping mode used in these moulds?

A: The paver moulds utilize injection mould technology, ensuring accurate shapes and smooth finishes in every paver block produced.Q: How does the lightweight design benefit users?

A: With a mould weight of approximately 500 grams, handling and demoulding is made easier, reducing operator fatigue and speeding up the production process.Q: What are the advantages of using plastic as the mould base?

A: Plastic bases offer resistance to wear and tear, lightweight handling, and long-term usability, making them ideal for repetitive industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

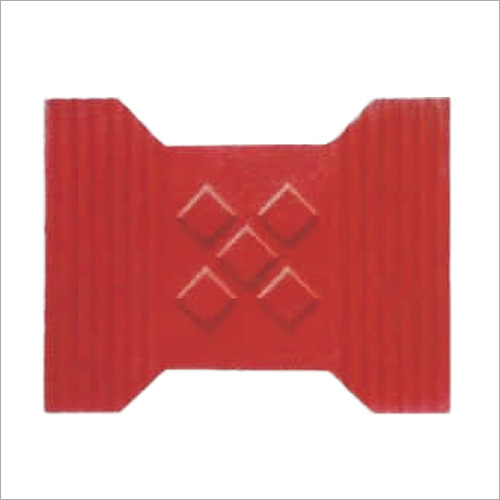

Grooks Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Material : Plastic

Mould Weight : Approx 500 Grams (g)

Molding Material : Concrete mix, resin

Usage : Industrial

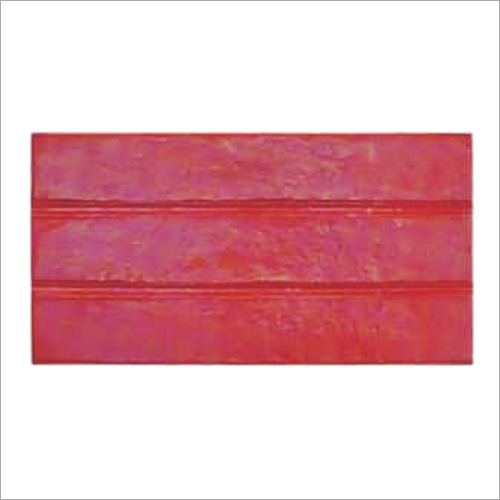

Coasmic Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Material : Plastic

Mould Weight : Approx 500 Grams (g)

Molding Material : Concrete mix, resin

Usage : Industrial

Falcon Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Material : Plastic

Mould Weight : Approx 500 Grams (g)

Molding Material : Concrete mix, resin

Usage : Industrial

Stone Effect Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Material : Plastic

Mould Weight : Approx 500 Grams (g)

Molding Material : Concrete mix, resin

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry