Coasmic Paver Moulds

Coasmic Paver Moulds Specification

- Molding Material

- Concrete mix, resin

- Mold Base

- Plastic

- Shaping Mode

- Injection Mould

- Usage

- Industrial

- Material

- Plastic

- Size

- Standard

- Mould Weight

- Approx 500 Grams (g)

Coasmic Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Coasmic Paver Moulds

Versatile Molding Solutions

Engineered from durable plastic, Coasmic Paver Moulds are compatible with both concrete mix and resin, making them a perfect choice for various paving requirements. Their standard size and injection moulding technique ensure uniformity, facilitating efficient mass production and consistent quality for industrial clients.

Industrial-Grade Quality and Performance

These moulds weigh approximately 500 grams, offering an optimal balance between durability and easy handling. Whether used by manufacturers, importers, or service providers, Coasmic Paver Moulds are built to withstand repetitive industrial usage while maintaining precision and reliability.

FAQs of Coasmic Paver Moulds:

Q: How are Coasmic Paver Moulds used in the industrial paving process?

A: Coasmic Paver Moulds are filled with either a concrete mix or resin to create paver blocks. The mixture is poured into the mould, leveled, and then allowed to cure before demoulding. This process ensures that each paver features uniform shape and a high-quality finish.Q: What materials can be molded using Coasmic Paver Moulds?

A: These moulds are designed to accommodate concrete mix and resin, making them suitable for creating strong, versatile paver blocks used in industrial and commercial paving projects.Q: When should these paver moulds be demoulded after pouring the mix?

A: For best results, the concrete mix or resin should be allowed to cure adequately as per the manufacturers recommendationsusually, concrete requires 24 hours of curing, while resin may need less, depending on ambient conditions.Q: Where are Coasmic Paver Moulds typically used?

A: Coasmic Paver Moulds are widely utilized across industrial and construction sites in India for manufacturing paving blocks. They are favored by importers, suppliers, and service providers for large-scale paving and landscaping solutions.Q: What is the benefit of using injection-moulded plastic for these paver moulds?

A: Injection-moulded plastic provides superior durability, dimensional stability, and smooth finishes, resulting in long-lasting and precisely formed paver blocks. It also allows for easy cleaning and reuse.Q: How does the moulds standard size and weight contribute to its effectiveness?

A: The standard size ensures compatibility with most industrial paving requirements, while the approximate 500 grams weight makes the mould easy to handle, transport, and demould without compromising strength.Q: What are the primary advantages for manufacturers and suppliers using Coasmic Paver Moulds in India?

A: Manufacturers and suppliers benefit from the moulds consistent results, efficient workflow, low maintenance requirements, and robust build, supporting large-scale production with minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

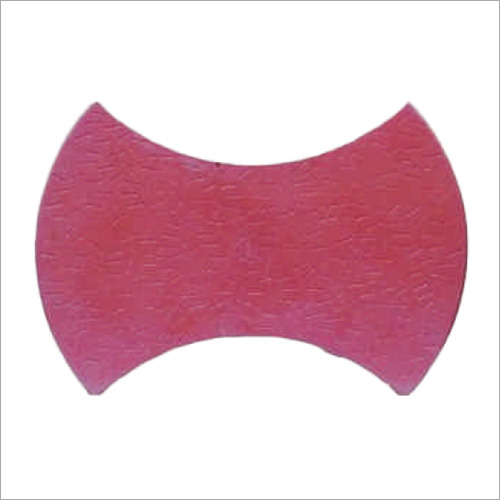

Damaru Paver Moulds

Minimum Order Quantity : 1 Unit

Mould Weight : Approx 500 Grams (g)

Mold Base : Plastic

Material : Plastic

Molding Material : Concrete mix, resin

Shaping Mode : Other, Paver Moulds

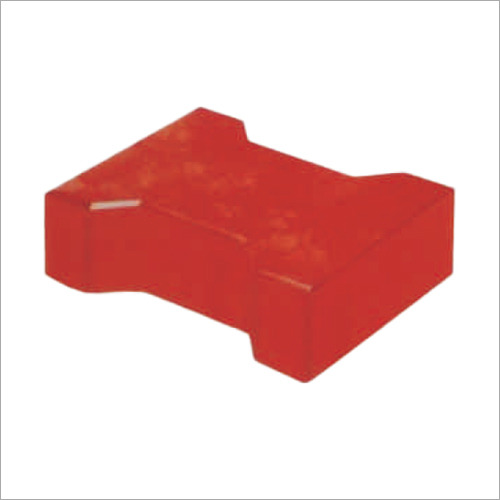

Falcon Plain Paver Mould

Minimum Order Quantity : 1 Unit

Mould Weight : Approx 500 Grams (g)

Mold Base : Plastic

Material : Plastic

Molding Material : Concrete mix, resin

Shaping Mode : Plastic Extrusion Mould

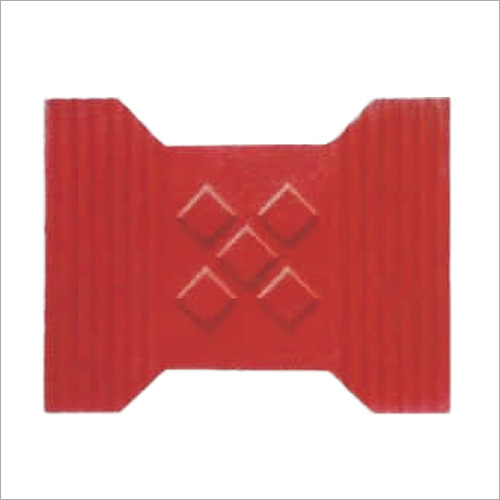

Falcon Paver Moulds

Minimum Order Quantity : 1 Unit

Mould Weight : Approx 500 Grams (g)

Mold Base : Plastic

Material : Plastic

Molding Material : Concrete mix, resin

Shaping Mode : Other

Reliance Paver Moulds

Minimum Order Quantity : 1 Unit

Mould Weight : Approx 500 Grams (g)

Mold Base : Plastic

Material : Plastic

Molding Material : Concrete mix, resin

Shaping Mode : Other, Paver Moulds

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry