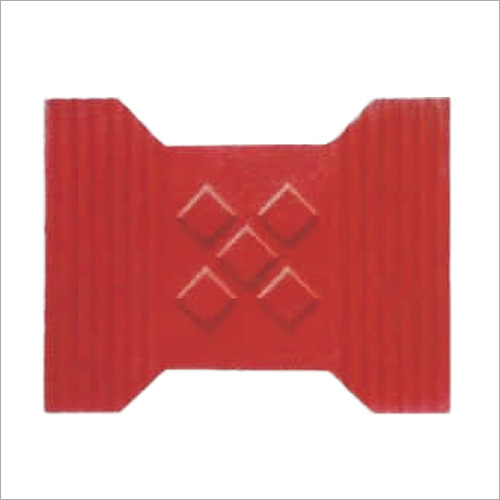

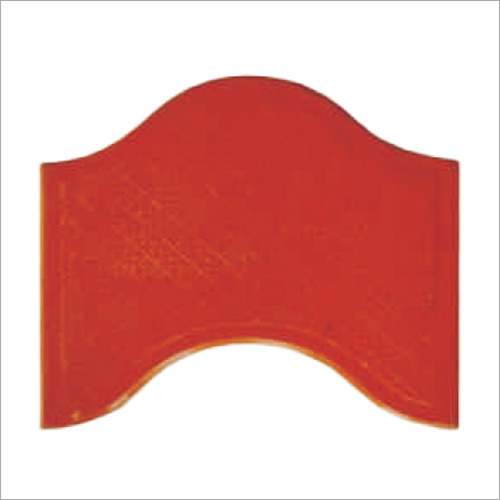

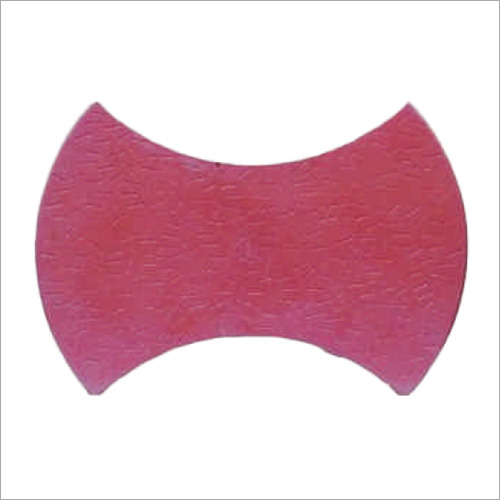

Vaves Paver Moulds

MOQ : 1 Unit

Vaves Paver Moulds Specification

- Mold Base

- Plastic

- Molding Material

- Concrete mix, resin

- Shaping Mode

- Injection Mould

- Usage

- Industrial

- Material

- Plastic

- Size

- Standard

- Mould Weight

- Approx 500 Grams (g)

Vaves Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Vaves Paver Moulds

Our firm has carved a special niche in this domain by presenting an exquisite collection of Vaves Paver Moulds. It is broadly used to make tiles as well as bricks, which are suitable for wall flooring and cladding purposes. It ensure rigid strength, fine finishing, easy to clean, high durability and flexible adjustments. Vaves Paver Moulds comes in an eye catchy colors and contemporary thicknesses to render appealing look of interior or exterior floorings.

Precision-Engineered for Industrial Use

Vaves Paver Moulds are crafted using advanced injection moulding processes to ensure each moulds accuracy and consistency. Their plastic construction is tailored for intensive industrial use, delivering high-strength pavers suitable for varied environments. The light design simplifies transport and handling, making them a reliable choice for paving professionals.

Versatile Compatibility with Concrete and Resin

The moulds are compatible with both concrete mix and resin materials, offering flexibility for users seeking different finishes and strengths. Whether for heavy-duty industrial floors or decorative outdoor pathways, Vaves Paver Moulds support a broad range of paving solutions.

FAQs of Vaves Paver Moulds:

Q: How are Vaves Paver Moulds used in industrial paving projects?

A: Vaves Paver Moulds are primarily filled with a concrete mix or resin, compacted, then cured to form uniform paver blocks. Their standard size ensures easy integration with most paving designs in industrial environments.Q: What material are these paver moulds made from?

A: These moulds are made from high-quality plastic engineered to withstand repeated usage and the pressures of industrial-scale production. Their injection-moulded construction guarantees stability and durability.Q: When should I use resin instead of concrete mix in Vaves Paver Moulds?

A: Resin is generally used when a smoother, more decorative finish or a lighter-weight paver is desired. For more robust applications, like load-bearing areas, concrete mix is recommended.Q: Where can Vaves Paver Moulds be sourced in India?

A: Vaves Paver Moulds are available across India through the companys network as an importer, manufacturer, service provider, and supplier. They can be procured directly from Vaves or authorized distribution partners.Q: What is the moulding process for creating pavers using these moulds?

A: Simply prepare the desired concrete or resin mix, pour it into the plastic mould, vibrate or tap to remove air bubbles, and allow the mix to cure. Once fully set, demould the paver for use.Q: How does using Vaves Paver Moulds benefit industrial paving operations?

A: These moulds provide improved efficiency by ensuring consistent, uniform paver shapes. Their durability allows for repeated use, which reduces costs over time and supports large-scale production requirements.Q: What are the maintenance requirements for Vaves Paver Moulds?

A: Regularly clean the moulds after each use to remove residue and prolong their lifespan. Store them in a cool, dry place to maintain their shape and effectiveness for future production cycles.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paver Block Moulds Category

Falcon Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other

Mold Base : Plastic

Material : Plastic

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Grooks Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Paver Moulds

Mold Base : Plastic

Material : Plastic

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Reliance Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Paver Moulds

Mold Base : Plastic

Material : Plastic

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Damaru Paver Moulds

Minimum Order Quantity : 1 Unit

Shaping Mode : Other, Paver Moulds

Mold Base : Plastic

Material : Plastic

Usage : Industrial

Mould Weight : Approx 500 Grams (g)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free