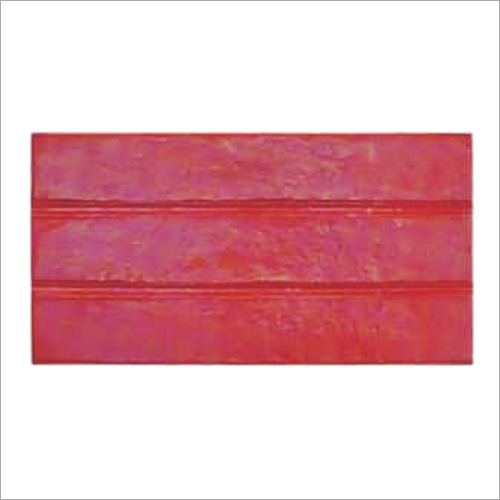

Stone Effect Paver Moulds

Stone Effect Paver Moulds Specification

- Mold Base

- Plastic

- Molding Material

- Concrete mix, resin

- Shaping Mode

- Paver Moulds

- Usage

- Industrial

- Material

- Plastic

- Mould Weight

- Approx 500 Grams (g)

Stone Effect Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Stone Effect Paver Moulds

Authentic Stone Texture Made Easy

These paver moulds are designed to replicate the natural look of stone, combining practicality with high aesthetic value. The plastic construction guarantees strength while enabling detailed patterns, making it simple to decorate outdoor and industrial spaces with professional results.

Efficient, Versatile Industrial Usage

Our stone effect moulds serve a variety of industrial purposes and can be used with both concrete mix and resin. Whether you are constructing large outdoor areas or smaller decorative details, these moulds ensure uniformity and ease of production, reducing waste and saving time on the job site.

FAQs of Stone Effect Paver Moulds:

Q: How do I use the Stone Effect Paver Moulds for my industrial paving projects?

A: To use the moulds, prepare your chosen molding material (either concrete mix or resin), pour it into the plastic paver mould, and let it set. Once hardened, simply demould to achieve a consistent stone effect on your pavers, ready for installation.Q: What materials can be used with these paver moulds?

A: These moulds are compatible with both concrete mix and resin. For a sturdy, authentic stone finish, concrete is commonly used, while resin can offer lighter or decorative options depending on your project needs.Q: When is it best to demould the pavers once the mixture is set?

A: Demoulding should be done once the material is fully set and hardened, which typically takes 24 to 48 hours for concrete and a shorter curing time for resin. Ensure the material is solid to avoid damaging the stone effect detail.Q: Where can these stone effect paver moulds be used?

A: These moulds are ideal for outdoor applications in landscaping, walkways, patios, garden paths, and industrial paved areas. Their uniformity and ruggedness make them suitable for both decorative and heavy-use spaces.Q: What benefits do these plastic base moulds offer over traditional alternatives?

A: The plastic base provides durability, lightweight handling (approx 500 grams), and resistance to sticking, which streamlines the demoulding process. This results in higher production speed and less wear on the moulds compared to conventional options.Q: How does the manufacturing process ensure accurate stone texture and consistency?

A: Our manufacturing process uses advanced shaping techniques to replicate authentic stone patterns. The plastic moulds are precision-engineered to deliver consistent detailing and uniform sizes across batches, meeting strict industrial standards.Q: What support services do you offer for industry clients in India?

A: As an importer, manufacturer, service provider, and supplier, we offer comprehensive support including bulk supply, customization guidance, and after-sales service to ensure our clients across India achieve optimal results with our stone effect paver moulds.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

Zig Zag Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Mould Weight : Approx 500 Grams (g)

Usage : Industrial

Shaping Mode : Plastic Extrusion Mould

Molding Material : Concrete mix, resin

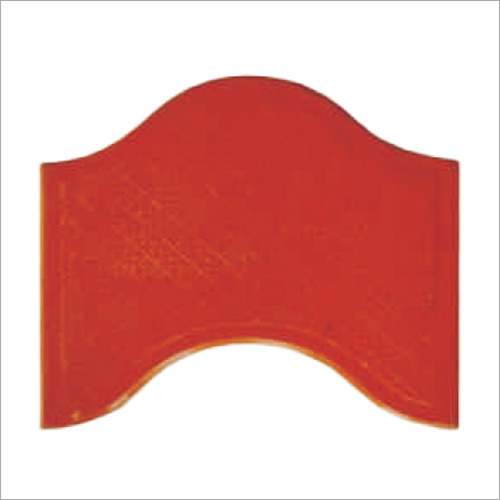

Reliance Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Mould Weight : Approx 500 Grams (g)

Usage : Industrial

Shaping Mode : Other, Paver Moulds

Molding Material : Concrete mix, resin

Grooks Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Mould Weight : Approx 500 Grams (g)

Usage : Industrial

Shaping Mode : Other, Paver Moulds

Molding Material : Concrete mix, resin

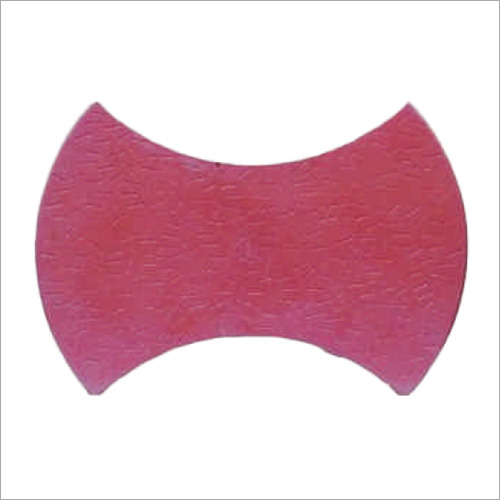

Damaru Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Mould Weight : Approx 500 Grams (g)

Usage : Industrial

Shaping Mode : Other, Paver Moulds

Molding Material : Concrete mix, resin

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry