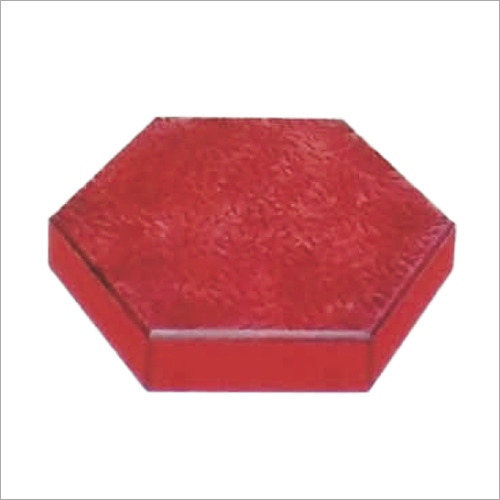

Hexagon Paver Moulds

Hexagon Paver Moulds Specification

- Mold Base

- Plastic

- Shaping Mode

- Other

- Usage

- Industrial

- Material

- Plastic

- Size

- Standard

- Mould Weight

- Approx 500 Grams (g)

Hexagon Paver Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Hexagon Paver Moulds

Precision Manufacturing for Consistent Quality

Our Hexagon Paver Moulds are crafted using superior plastic materials to guarantee uniformity and durability in every batch of paver tiles produced. The standard sizing ensures compatibility with industrial setups, minimizing variation and maximizing production efficiency. Each mould undergoes quality checks before shipping, supporting reliable performance in demanding environments.

Applications and Benefits

Suitable for various paving requirements, these moulds are widely used in landscaping, road construction, and urban infrastructure projects. Their robust plastic composition resists deformation, enabling repeated, cost-effective use. Using these moulds speeds up production, reduces wastage, and delivers professional-grade results regardless of the volume needed.

FAQs of Hexagon Paver Moulds:

Q: How are Hexagon Paver Moulds used in industrial manufacturing?

A: They are filled with concrete or similar materials, vibrated to eliminate air bubbles, and allowed to set. Once cured, the paver is demoulded, yielding a precise hexagonal shape suitable for paving applications.Q: What material is used in making these paver moulds, and why?

A: Our paver moulds are made from high-strength plastic, chosen for its durability, easy maintenance, and capacity to reliably reproduce precise shapes over many production cycles.Q: When should these moulds be replaced during production?

A: Replacement is generally recommended if the mould shows signs of warping, cracks, or significant wear, which could affect the accuracy of the produced pavers. Under normal industrial use, they boast an extended service life.Q: Where can these Hexagon Paver Moulds be sourced in India?

A: We serve as an importer, manufacturer, service provider, and supplier of Hexagon Paver Moulds throughout India, offering both bulk and customized solutions for industrial needs.Q: What is the typical process for creating pavers using these moulds?

A: The process involves preparing the concrete mixture, filling the plastic moulds, vibrating to remove air, allowing the mix to set, and then releasing the cured paver from the mould for further finishing or installation.Q: How does the weight of the mould benefit industrial users?

A: The approx 500-gram weight ensures easy manual handling, swift production cycles, and reduced fatigue for workers, contributing to higher productivity and operational efficiency.Q: What are the primary benefits of choosing plastic hexagon paver moulds over other materials?

A: Plastic moulds offer superior reusability, resist concrete adhesion, provide consistent paver dimensions, and require minimal maintenance, all of which contribute to long-term cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Moulds Category

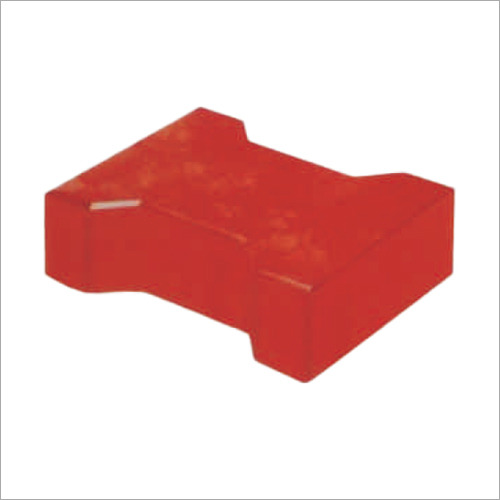

Reliance Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Material : Plastic

Usage : Industrial

Molding Material : Concrete mix, resin

Shaping Mode : Other, Paver Moulds

Zig Zag Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Material : Plastic

Usage : Industrial

Molding Material : Concrete mix, resin

Shaping Mode : Plastic Extrusion Mould

Jumbo Colorado Paver Moulds

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Material : Plastic

Usage : Industrial

Molding Material : Concrete mix, resin

Shaping Mode : Other, Paver Mould

Falcon Plain Paver Mould

Minimum Order Quantity : 1 Unit

Mold Base : Plastic

Material : Plastic

Usage : Industrial

Molding Material : Concrete mix, resin

Shaping Mode : Plastic Extrusion Mould

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry