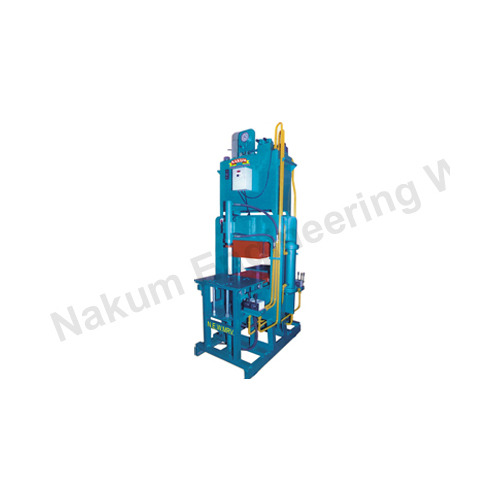

Paver Block Making Machine

Paver Block Making Machine Specification

- Surface

- Coated

- General Use

- Construction

- Material

- Mild steel

- Automatic

- Yes

- Method

- Hydraulic Pressure

- Voltage

- 220-440 Volt (v)

- Feature

- Easy to use

Paver Block Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units, , Per Month

- Delivery Time

- 2-10 Days

- Main Export Market(s)

- South America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Paver Block Making Machine

Paver Block Making Machine

As an eminent enterprise, we are offering very efficient Hydraulic Press Fly Ash Bricks Making Machine that is extensively demanded among customers owing to its high speed operations. This machine is precisely engineered using premium components to enhance its performance and productivity. Fly ash bricks are widely demanded in construction industries because of its light weight yet are sturdier to endure high weight. In order to make sure that this industrial Hydraulic Press Fly Ash Bricks Making Machine delivers flawless performance, we strictly examine its functioning before the final dispatch.

Superior Hydraulic Performance

Engineered with advanced hydraulic press technology and mold vibration, this machine delivers superior compaction, ensuring paver blocks with consistent density and structural strength. The high-pressure system allows for increased output while maintaining precise dimensions, making it a dependable choice for fast-paced construction environments.

User-Friendly and Automated Operation

The fully automated features, including PLC control and easy-to-use computerized panels, simplify production while minimizing manual intervention. Operators can manage processes efficiently, leading to consistent product quality and reduced labor costs. The automatic and user-friendly interface makes it ideal for businesses seeking streamlined block manufacturing.

Durability and Cost Efficiency

Constructed from high-quality mild steel and finished with a protected surface coating, the machine boasts exceptional durability. Its premium build and low-maintenance design reduce downtime and operational expenses, resulting in a highly cost-effective production process that maximizes profitability and long-term sustainability.

FAQs of Paver Block Making Machine:

Q: How does the hydraulic press system improve paver block production quality?

A: The hydraulic press system applies consistent, high pressure and mold vibration to the raw materials, resulting in paver blocks with uniform density, superior strength, and precise edges. This enhances durability and ensures that the blocks meet stringent quality standards for construction use.Q: What capacity can I expect from this paver block making machine?

A: You can expect a production capacity of up to 3,000 pieces per day, thanks to the machines high-pressure capabilities, automatic operation, and efficient production process, making it suitable for medium to large-scale projects.Q: When should I perform maintenance on this machine, and what are the requirements?

A: Routine maintenance, such as regular cleaning, lubrication, and inspection of components, is recommended at scheduled intervals based on usage intensity. The machines low-maintenance design minimizes disruptions, and detailed guidelines are provided in the user manual for optimal upkeep.Q: Where is this machine best suited for installation?

A: This machine is tailored for construction and industrial settings, including both outdoor and indoor environments where reliable electricity (220-440V) and space for heavy-duty equipment are available. Its versatile design accommodates variable installation dimensions.Q: What is the process for producing paver blocks using this machine?

A: The process involves loading the raw materials, selecting the desired mold and settings on the PLC panel, and initiating the automated cycle. The machine hydraulically presses and vibrates the mixture, forming durable blocks that are then easily ejected for curing.Q: How does the machines automatic and computerized features benefit users?

A: The integrated PLC control and computerized operation streamline production, reduce manual interventions, and ensure repeatable, high-quality output. They also enhance user safety and make the system accessible to operators with varying technical skills.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Making Machine Category

High Pressure Paver Block Making Machine

Minimum Order Quantity : 1 , , Unit

General Use : Construction and Industrial

Voltage : 440 Volt (v)

Automatic : Yes

Feature : Easy to use, High efficiency and Low power consumption

Method : Hydraulic Pressure

Paver Block Machine

Minimum Order Quantity : 1 Unit

General Use : Construction and Industrial

Voltage : 220440 Volt (v)

Automatic : Yes

Feature : Easy to use, High efficiency and Low power consumption

Method : Hydraulic Pressure

MS Paver Block Machine

Minimum Order Quantity : 1 Unit

General Use : Construction

Voltage : 220440 Volt (v)

Automatic : Yes

Feature : Stable performance

Method : Hydraulic Pressure

Industrial Paver Block Machine

Minimum Order Quantity : 1 Unit

General Use : Construction

Voltage : 220440 Volt (v)

Automatic : Yes

Feature : Stable performance

Method : Hydraulic Pressure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free